What is HACCP Certification?

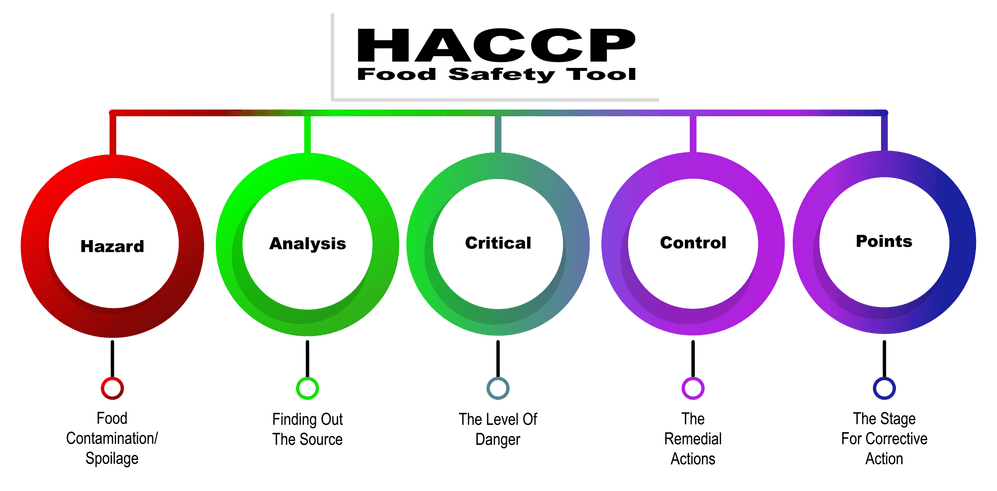

HACCP Stands for “Hazard Analysis and Critical Control Point.” It provides a structure for objective assessment of ‘what can go wrong’ and requires controls to be put in place to prevent problems. HACCP is a preventive food safety management system, and it is recognized internationally as the most effective way of producing safe food.

For implementing this system, HACCP Certification is required. Both Prerequisite Programs and HACCP Plans must be implemented as a system. The Prerequisite Programs ensure a hygienic environment and good manufacturing processes. The HACCP plans are for each process or product to identify possible hazards and required controls.

HACCP is a proactive approach to food safety that seeks to identify and eradicate hazards before they occur. All staff must know how to practice safe food hygiene to meet HACCP standards. If you are running a food business, you are legally required to implement a safety management system based on Hazard Analysis & Critical Control Point (HACCP) principles.

- The HACCP system is science-based and systematic, identifying specific hazards and measures for their control to ensure food safety.

- HACCP is a tool to assess hazards and establish control systems that focus on prevention rather than mainly on end-product testing.

Quick Navigation

HACCP History

The National Aeronautics and Space Administration (NASA) of the United States of America Sends space missions for various purposes. But the food to be provided to astronauts has to be safe as they will have no alternative food supplies in space. Pillsbury company, which was producing foods for space missions, has developed the HACCP concept for producing safe foods. This concept was first presented in 1971 at National Conference on Food Protection.

In the Year 1974, HACCP was included in regulations by USFDA for low acid canned foods. Subsequently, in the early 1980s, the HACCP concept gained acceptance in many other food industries. Now all international agencies like the Codex Aliment Arius commission also recommend using HACCP for ensuring food safety. Food Safety and standards authority of Pakistan also recommends the HACCP approach as part of the Food Safety Management Program.

Here’s A Video Tutorial About HACCP

What are the benefits of HACCP?

HACCP is widely adopted worldwide as the basis for food safety laws. The benefits of HACCP are

- It enhances food safety and reduces the risk of foodborne diseases.

- Provide greater confidence to customers.

- It helps in the reduction of production costs through reduced wastage.

- Facilities compliance with statutory requirements.

- Current or potential hazards can be identified and removed or minimized.

- It Provides continuous self-inspection and improvement.

- HACCP Helps with complaints and legal actions.

What are the 7 HACCP Principles?

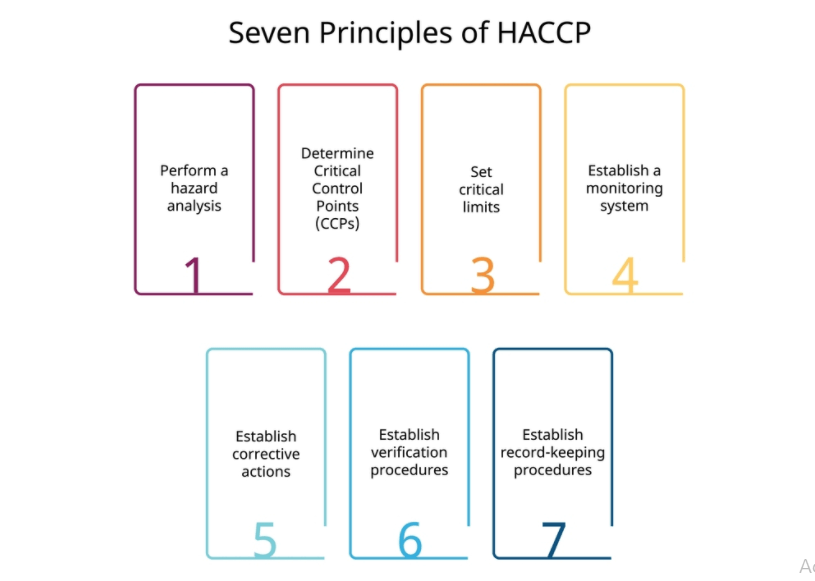

The goals of HACCP are to eliminate or significantly reduce the possibility of a hazard or food-borne illness and prevent a hazard from happening. HACCP is based on the following seven principles:

1) Conduct a Hazard Analysis

Plan to determine the food safety hazards and identify the preventive measures the plan can apply to control these hazards. A food safety hazard is any biological, chemical, or physical property that may cause a food to be unsafe for human consumption.

A hazardous analysis aims to develop a list of hazards that are likely to cause injury or illness if they are not controlled.

Points to be considered in this analysis can include:

- Skill level of employees

- Transport of food

- Serving elderly, sick, very young children, immune-compromised

- Volume cooling

- Thawing of potentially hazardous food

- The high degree of food handling and contact

- Adequacy of preparation and holding equipment available

- Storage and method of preparation.

The next step is determining if the factors may influence the likely occurrence and severity of the hazard being controlled. Finally, it should list the hazards associated with each step in the flow of food along with the measures necessary to manage the hazard.

2) Determine the Critical Control Points (CCPs)

Your CCPs are the steps at which controls be applied to prevent or eliminate the hazards. For each CCP, you will identify the preventive measure also. The HACCP helps you identify the exact CCPs of your process.

At the step in preparation, can food become contaminated, or can contamination increase?

- Can this hazard be prevented through corrective actions?

- Can this hazard be prevented, eliminated, or reduced by steps taken later in the preparation process?

- Can you monitor the CCP?

- How will you measure the CCP?

- Can you document the CCP?

3) Establish Critical Limits

A critical limit ensures that a CCP controls a biological, chemical, or physical hazard. Each CCP should have at least one essential limit. Required limits must be something that can be monitored by measurement or observation. They must be scientifically and regulatory based.

Examples: temperature, time, pH, water activity, or available chlorine.

4) Establish Monitoring Procedures

Monitoring is a plan which includes observations or measurements to assess whether the CCP is being met. It records the “flow of food” through the establishment. If monitoring indicates that the critical limits are not being met, then take action to bring the process back into control. The monitoring system should be easy to use and meet the needs of the food establishment and the regulatory authority. The job of monitoring must be assigned to a specific individual, and they are trained on the monitoring technique.

5) Establish Corrective Actions

When monitoring indicates a deviation from an established critical limit, these actions must be taken. The final rule requires a plant’s HACCP plan to identify the corrective actions to be taken if a critical limit is not met. Disciplinary actions are intended to ensure that no product is injurious to health or otherwise adulterated if the deviation enters commerce.

If the criteria for a CCP are not being met, some type of corrective action must be taken. They must meet the standards established in Step 3, based on normal working conditions, and be measurable. Disciplinary actions may range,

For Example: from “continue cooking until the established temperature is reached” to “throw out the product” depending on the severity of the situation.

HACCP plans should include who is responsible for implementing the corrective action and what corrective action was taken. They should be established in advance as part of the HACCP plan.

6) Establish Verification Procedures

These procedures are activities other than monitoring that determine the validity of the HACCP plan and that the system is operating according to the plan. Verification is important to determine if the project is scientifically and technically sound.

Also, all the hazards can be effectively controlled. Verification can be accomplished by expert advice and scientific studies, observations of food flow, measurements, and evaluations. Another means of verification is an on-site review of the established critical limits. Each CCP will have one independent authority. This verification step provides an opportunity to modify the plan if necessary.

7) Establish Documentation Procedures

The HACCP regulation requires that all plants maintain certain documents, including its hazards analysis and written HACCP plan, and records documenting critical control points, critical limits, verification activities, and handling processing deviations. Implementing involves monitoring, verifying, and validating the daily work that is compliant with regulatory requirements in all stages all the time.

Record-keeping and documentation procedures should be simple to complete and include information illustrating that the established standards are being met. Employees need to be trained on record-keeping procedures and why it is critical to their job.

Examples: Records include time/temperature logs, checklists, forms, flowcharts, employee training records, and SOP.

What is the Application of HACCP?

The HACCP system can be used at all stages of a food chain, from food production and preparation processes to packaging, distribution, etc. HACCP has been increasingly applied to industries other than food, such as cosmetics and pharmaceuticals. The following steps include in the application of the HACCP system:

1) Assemble HACCP Team

The food operation should ensure that the appropriate Product-specific knowledge and expertise are available to develop an effective HACCP plan. Optimally, this may accomplish by assembling a multidisciplinary team. Where such expertise is not available on-site, should obtain expert advice from other sources, such as trade and industry associations, independent experts, regulatory authorities, HACCP literature, and HACCP guidance.

A well-trained individual with access to such guidance may possibly implement HACCP in-house. The scope should describe which segment of the food chain is involved and the general hazards to address (e.g., does it cover all classes of hazards or only selected classes).

2) Describe the Product

A full description of the Product should be drawn up, including relevant safety information such as Composition, physical/chemical structure (Including Aw, pH, etc.), microbial/static treatments (heat treatment, freezing, brining, smoking, etc.), packaging, durability and storage conditions and method of distribution.

Within a business with multiple products, for example, catering operations, it may be adequate to group products with similar characteristics of processing steps to develop the HACCP plan.

3) Identify Intended Use

The intended use should be based on the expected uses of the Product by the end-user or consumer. In specific cases, vulnerable groups of the population, e.g., institutional feeding, may have to be considered.

4) Construction Flow Diagram

The HACCP team should construct the flow diagram. The flow diagram should cover all steps in operation for a specific product. The same flow diagram may be used for several manufactured products using similar processing steps. When applying HACCP to a given operation, the steps preceding and following the specified operation should be considered.

5) On-Site Confirmation of Flow Diagram

Steps must be taken to confirm the processing operation against the flow diagram during all stages and hours and amend the flow diagram where appropriate. The confirmation of the flow diagram should be performed by a person or persons with sufficient knowledge of the processing operation.

6) Conduct Hazard Analysis

The HACCP team should list all the hazards that may be reasonably expected to occur at each step according to the scope from primary production, processing, manufacture, and distribution until the point of consumption.

The HACCP team should conduct a hazard analysis to identify for the HACCP plan which hazards are of such a nature that their elimination or reduction to acceptable levels is essential to producing safe food.

7) Determine Critical Control Points

There may be more than one CCP where control is applied to address the same hazard. The determination of a CCP in the HACCP system can be facilitated by applying a decision tree, which indicates a logical reasoning approach. The application of a decision tree should be flexible, given whether the operation is for production, slaughter, processing, storage, distribution, or other. It should be used for guidance when determining CCPs.

This example of a decision tree may not apply to all situations. Other approaches may be used. Training in the application of the decision tree is recommended. Suppose a hazard has been identified where control is necessary for safety, and no control measure exists at that step or any other. In that case, we should modify the Product or process to include a control measure.

8) Establish Critical limits for each CCP

Critical limits must be specified and validated for each Critical Control Point. More than one critical limit will be elaborated at a certain step in some cases. Criteria often used include temperature, time, moisture level, pH, Aw, available chlorine, and sensory parameters such as visual appearance and texture.

Where experts have developed HACCP guidance to establish the critical limits, care should be taken to ensure that these limits apply to the specific operation, Product, or groups of products under consideration. These critical limits should be measurable.

9) Establish a monitoring system for each CCP

Monitoring is the scheduled measurement or observation of a CCP relative to its critical limits. The monitoring procedures must detect loss of control at the CCP. Further, monitoring should ideally provide this information in time to make adjustments to ensure process control to prevent violating the critical limits. Process adjustments should be made where monitoring results indicate a trend towards losing control at a CCP.

The adjustments should be taken before a deviation occurs. A designated person with knowledge and authority must evaluate data derived from monitoring to carry out corrective actions when indicated. Most monitoring procedures for CCPs will need to be done rapidly because they relate to online processes. There will not be measurements often referred to as microbiological testing because they may be done rapidly and can often indicate the microbiological control of the Product.

All records and documents associated with monitoring CCPs must be signed by the persons doing the monitoring and by responsible reviewing company officials.

10) Establish Corrective Actions

Specific corrective actions must be developed for each CCP in the HACCP system to deal with deviations when they occur.

The actions must ensure that the CCP has been brought under control. Actions taken must also include proper disposition of the affected Product. Deviation and product disposition procedures must be documented in the HACCP record keeping.

11) Establish Verification Procedures

Establish procedures for verification; Verification auditing methods, procedures, and tests, including random sampling and analysis, can be used to determine if the HACCP system is working correctly. The frequency of verification should be sufficient to confirm that the HACCP system is working effectively.

Verification should be done by someone other than the person responsible for monitoring and corrective actions. Where certain verification activities cannot be performed in-house, external experts or qualified third parties should perform verification on behalf of the business.

12) Establish Documentation and Record-Keeping

Efficient and accurate record-keeping is essential to the application of a HACCP system. HACCP procedures should be documented. Documentation and record-keeping should be appropriate to the nature and size of the operation and sufficient to assist the business in verifying that the HACCP controls are in place and being maintained. Expertly developed HAACP guidance materials may be utilized as a part of the documentation, provided those materials reflect the specific food operations of the business.

A simple record-keeping system can be effective and easily communicated to employees. It may be integrated into existing operations and use paperwork, such as delivery invoices and checklists, to record, for example, product temperatures.

How to Get HACCP Certification?

HACCP is an internationally used standard in food manufacturing, processing, treatment, and service organizations. HACCP application is a constitutional requirement for food industries in many countries. The association with a quality management system enables the food industry to manage the safety of food products under the defined management system structure. HACCP principles require identifying the vital control points in the manufacturing or service progressions and set-ups up food safety controls.

To become HACCP certified, you must successfully pass a third-party certification audit provided by a qualified food safety auditor. The idea of an audit can be a source of anxiety, even for businesses that embrace HACCP principles. But the process doesn’t need to be a negative experience.

HACCP Certification in Pakistan

The HACCP Certification in Pakistan is not an easy task as there are several verification procedures and steps. Many restaurants and companies will hire a HACCP team to handle the burden of developing and writing a HACCP plan and the implementation process.

TUV Austria Bureau of Inspection & Certification has developed a methodical specification of requirements for an operational HACCP system for audit and certification for the food manufacturing and service industries.

The fact that we can provide the best services at the expert level enables us to take customer satisfaction to another level. Our services have a fast turnaround to let you enjoy prime certification and many more.

What is HACCP Certification Cost?

A HACCP Certification also reflects that you can trust your business for fair trade practices and ethical business strategies. Getting a HACCP certification is structured and systematic with a preventive approach to food safety. We ensure that the certification process is as simple and speedy as feasible. Just like our top-quality services, our prices, too, are unmatched.

We also document every stage of the certification process to increase your odds of success. We charge affordable prices for businesses, irrespective of their size and reach. Our prices are made much cheaper by our arrangement of remote management.

PLAN-DO-CHECK-ACT

To summarize, this implementation of the HACCP protocol involves the following steps:

PLAN: Identity what needs to be done to maintain food safety and write it down.

DO: Carry out the actions required to maintain food safety that you identified in the planning stage.

CHECK: Verify that you are doing what you planned to do to maintain food safety. Maintain a written record of what was checked, by whom, and when.

ACT: Remedy any food safety problems you identify and update your records to reflect when and what action was taken.

Why Choose Us?

TUV Austria Bureau of Inspection & Certification is ideally the right solution for you. We are a company specializing in food safety certification and primary production. We are glad to have a team of extremely skilled and efficient auditors who enable us to continue providing our best product quality and food safety management services. Our renowned accreditation has lent us the professional ability to perform audits and verification and a thorough, timely inspection of food quality and all the related management systems at regular intervals.

We offer our clients a wide range of services in the food and primary production industry. We have taken it upon ourselves to ensure that all our clients continue to consistently provide the best of products so that their position in the market does not get hampered. This dedication and passion for this industry have allowed us to emerge as leaders when it comes to heading the pack for HACCP Certification.

We also provide the renowned ISO 22000 certification services, which define a particular company’s ability in terms of dedication to producing safe foods. We, as a team, work towards arriving at an equilibrium state where both our clients and the needed customers can reap the benefits of the way we transform knowledge into value.

You need not worry about the standards of your products because if you chose us to hand over the crucial responsibility of enabling your business to be on par with the highest food quality, you would have made the perfect decision. This is because we utilize our experience to support you as a unique certification firm.

The experts on our team possess a combined experience of many years, and we constantly strive to utilize that to the optimum. Our experts are also updated with the legalities involved in such technical aspects. To put it in a nutshell, our industry expertise has helped us confidently serve as a firm that has solutions for various aspects related to your business needs.

TUV Austria Bureau of Inspection & Certification’s vast umbrella of certification services includes:

- ISO 9001 – Quality Management System

- ISO 14001 – Environmental Management System

- ISO 45001 – Occupational Health & Safety Management System

- ISO 55001 – Asset Management — Management Systems Requirements

- ISO 27001 – Information Security Management System

- ISO 20000 – IT Service Management System

- ISO 22000 – Food Safety Management System

- Halal Certification

- ISO 21001 – Educational Organizations Management System

- ISO 29990 – Learning Services Management System

- ISO 20121 – Sustainability Event Management System

- ISO 22301 – Business Continuity Management System

- ISO 37001 – Anti-Bribery Management System

- ISO 28000 – Supply Chain Security Management System

- ISO 13485 – Quality Management Systems for Medical Devices

- ISO 39001 – Road Traffic Safety Management System

- ISO 31000 – Risk Management – Guidelines

- ISO 22716 – Good Manufacturing Practices for Cosmetics

FAQS

What is HACCP?

HACCP is an internationally recognized food safety management system that identifies Critical Control Points (CCPs) during food preparation and production critical to food safety and implements control to ensure food is safe for consumption. Hazards can be anything microbiological, chemical, or physical that threatens safe food production. In simple terms, It involves identifying what could go wrong in a food system and planning how to prevent it.

What Does HACCP Stand for?

HACCP is an abbreviation for Hazard Analysis and Critical Control Points. The HACCP system identifies and controls three potential food safety hazards: Biological, Chemical, and Physical, and is all about PREVENTION.

What is HACCP Plan?

A HACCP plan can be used to control any area that could introduce potential biological, chemical, or physical hazards into the food stream. Whether illness-inducing microorganisms, contaminants, chemicals, raw materials, unsafe processes, package labeling, or storage conditions, the HACCP plan is designed to establish critical safety limits and prevent and control potential hazards.

Why Should You Use HACCP?

Awareness of food-borne illness is increasing, and concern throughout the industry drives using HACCP and HACCP certification programs.