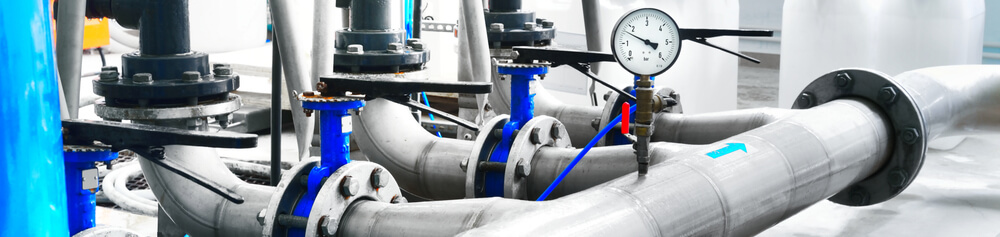

What is Pressure Equipment Directive (PED)?

The Pressure Equipment Directive 97EC of the EU sets out the standards for the design and fabrication of pressure equipment generally over one liter in volume and having a maximum pressure of more than 0.5 bar gauge. It also sets the “conformity assessment” requirements for pressure equipment, free placing on the market without local legislative barriers. It has been mandatory throughout the EU since 30 May 2002.

Quick Navigation

What is PED Certification?

PED Certification is a European Legislation aimed at removing the technical barriers to trade relating to the supply of pressure equipment throughout Europe. The PED is based on Essential Safety Requirements (ESRs) that have proven design, manufacturing, inspection, and testing. PED affects most equipment that will be placed on the market in the European Economic Area (EEA) designed for pressure.

- PED Certification is a symbol of product safety.

- PED aimed at removing the technical barriers to trade relating to the supply of pressure equipment.

- The PED is based on Essential Safety Requirements (ESRs) that grove design, manufacturing, inspection, and testing.

The aspects of the design, production, and testing of the various equipment are subjected to many standards, many of which are still being produced by the legislature. These standards cover all aspects of equipment design and production, like dimensions, materials, welding, and test methods.

Therefore, these standards play a vital role in assuring the product to both the customers and the manufacturer. As a Manufacturer, one has many responsibilities and details to consider during the production of pressure equipment and their testing.

The PED Certification is an assurance mark that provides agreement with safety requirements on pressure equipment like the following procedures:

- Analysis of Hazards.

- Material Selection.

- Calculations for Capacity.

- Calculations for Security.

- Calculations for Operation.

- Manufacturing and Welding Process.

- CE Marking.

However, Inspections and conformity procedures are different for each category, ranging from self-certification for the lowest hazard category to completing ISO 9001 inspection services for notified bodies. The assessment procedures come in other modular structures, and manufacturers select a test based on their requirements.

It is essential to have qualified personnel and appropriate procedures in place for specific processes and execute the work accordingly.

With PED Certification, the actual requirements for any equipment under the directive are very complex and depend on the design and the type of user, the intended use, and sometimes even the sales literature. Getting a product approved by certification allows complete freedom to be placed in the market and get returns without hassle. Read More…

What are the Benefits of PED Certification?

The benefits of PED Certification are:

What Documents are required for PED Certification?

- Technical File, Product Master File (TCF)

- Product Testing

- System Manual

- System Procedure

- Policy

- Objectives

- Mission & Vission

- Plant Master File

- Standard Opening Procedure

- Checklist

- Forms

- Formats

- Records

Our Pressure Equipment Directive (PED) Certification Services Include:

- Witnessing Hydrostatic Testing.

- Verification of Welding Files

- Type examination and approval.

- Safety Devise and Connection Control Approval.

- Quality System Approval.

- Periodic Inspections and Audits.

- Material Approval.

- Field Inspection and Coordination.

- Design examination.

- Approval of Joining Personnel and Procedures.

- Determination of Intrinsic Boiler Water Quality.

TUV Austria Bureau of Inspection & Certification’s huge umbrella of services includes:

- Third Party Inspection Services

- Pre-Shipment Inspection Services

- Risk-Based Inspection Services

- Crane Inspection Services

- Lifting Equipment Inspection Services

- QA / QC Services

- Construction Supervision Services

- Technical Manpower Supply Services

- Non Destructive Testing (NDT) Services

- Storage Tank Inspection Services

- Pressure Vessel Inspection Services

FAQS

Who can be certified in PED Certification?

- Pressure Vessels

- Piping

- Steam Generators

- Pressure Accessories

- Safety Accessories

- Steam Boilers

What are the focus points of implementing the PED Certificate?

- Accountability of product manufacturing process and procedure.

- Best practices for the safety of the product.

- Establish a flowchart, design, and diagram of the product.

- Determine the characteristics of the product by testing.